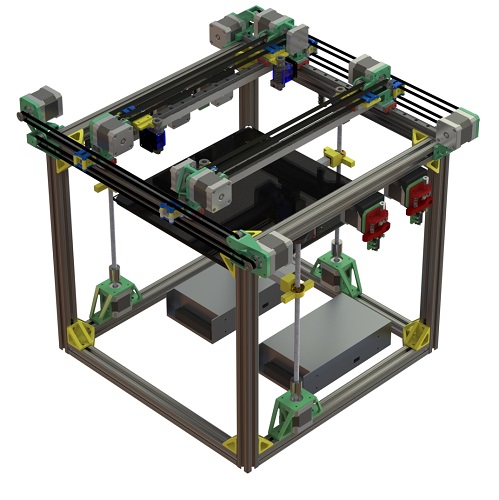

12d Printer

What do you do when your Facebook internship goes remote and you have money to burn?I'm going to address the elephant in the room: its a ridiculous idea. A printer with multiple print heads that work collaboratively. In this case multiple means four. Imagine a pinter with four print heads working together. They could print a part in 1/4 of the time!. This is truly the future.

Honestly, it started as something to do. I told some people and they said its not possible. Never one to back down from a vague challenge with no clear reward, I just went right to CAD. Slowly it took shape and, at least mechanically, was way more feasible than anyone expected. The mechanical design was inspired by the new-ish Ender 5 3D printer. About a month and $800 later I had all the parts I needed. (I feel its necessary to say that I'm generally good with money; but this summer I was getting a California housing stipend and living in College Station; I had quite a bit of disposable income).

The printer went together mechanically fairly easily. There really wasn't any glaring problems with how it was designed. I was later able to use the mechanical structure for my CSCE 462 project: a webapp for controlling stepper motors. However the software was chaotic. I knew this would be a major software hurdle; there was only one other person in the world (publically) thinking about this with any seriousness and it was on Reddit. Knowing that I was coming up on having to decide between doing a capstone and a research project, I got in touch with Dr. Shell (who did research on robots and planning) and ended up tackling the planning side of the problem as my Undergraduate Research Thesis. Thats right, I used this project for nine credit hours and as my capstone. For $800 that was a bargain. Wait you still have to pay for the research course even if you bring your own project and materials?

Of corse its not that simple: the controls side was a major pain point and ultimately why no real finished prototype ever existed. It came down to that I needed to control 12 stepper motors concurrently with real(ish) time guarantees. No existing (open source) solution had that opportunity. Grbl can do three and a fourth mirroring one of the others. Marlin can do five, but thats only half of whats needed. In the end, I got busy with other projects and being a TA. I intend to go back some day but the death certificate may have been signed when I scavenged the stepper motors for my SCARA Arm in early 2022.

Looking back, I'm still really happy with the design; I hadn't done much design since the Marble Sorter some two+ years prior. The system mechanically worked and I managed to pack four print heads into an printer with the a slightly larger build volume and about the same exterior dimensions as the Ender 5 Pro. Maybe someday someone will write the control software that gets this whole style of printer off the ground.

See also: CSCE 462 project for as built pics.

Overall system view